Advanced digital tools and technologies like 3D printing and AI-driven systems transform storm damage collision repair. Real-time data capture, precise measurements, and immediate estimates speed up claims processing and repairs. 3D printing offers faster, more efficient part creation, reducing lead times and costs. Modern equipment and automated systems enhance accuracy, minimize human error, and prioritize tasks for swift vehicle restoration after storms, ensuring enhanced safety and reduced downtime.

In the face of severe weather events, efficient storm damage collision repair is paramount. Advanced technology plays a pivotal role in enhancing this process, ensuring swift and accurate restoration of vehicles affected by storms. This article explores how digital tools streamline assessment of storm damage, 3D printing revolutionizes auto parts replacement, and enhanced safety features accelerate the entire repair process, ultimately revitalizing vehicles and alleviating post-storm stress.

- Digital Tools Streamline Storm Damage Assessment

- 3D Printing Revolutionizes Auto Parts Replacement

- Enhanced Safety Features Accelerate Repair Process

Digital Tools Streamline Storm Damage Assessment

In the aftermath of a storm, assessing damage across numerous vehicles can be a daunting task. However, digital tools are transforming this process in storm damage collision repair. From initial surveys to detailed inspections, mobile apps and cloud-based software allow for real-time data capture. Technicians can document dents, scratches, and other hail damage or the aftermath of a fender bender with precise measurements and high-resolution images, streamlining the claims process and enabling faster turnaround times for dent repair and other necessary fixes.

This digital revolution offers more than just convenience; it enhances accuracy and efficiency. By comparing damaged vehicles to pre-existing databases and utilizing advanced algorithms, these tools can provide immediate estimates for both minor repairs like hail damage repair and more significant storm damage collision repair needs. This not only expedites the entire process but also helps in securing fair compensation for vehicle owners, ensuring they receive the best possible service following a severe weather event.

3D Printing Revolutionizes Auto Parts Replacement

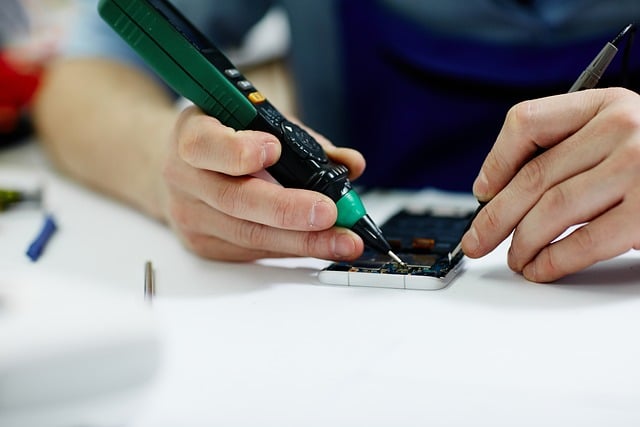

The automotive industry is experiencing a significant transformation with the advent of advanced technologies, particularly 3D printing, which is revolutionizing storm damage collision repair. This innovative process offers a faster and more efficient solution for replacing auto parts, especially in cases of severe weather-related collisions. By using digital designs, 3D printers can create precise replicas of vehicle bodywork, including complex components like bumpers, fenders, and grilles.

This technology streamlines the vehicle repair process by eliminating the need for traditional manufacturing methods and reducing lead times. With 3D printing, specialized auto parts can be produced on-demand, tailored to the specific requirements of each storm damage collision. This not only enhances the quality of repairs but also contributes to cost savings, faster turnaround times, and a more sustainable approach to vehicle bodywork replacement, ensuring that damaged vehicles are restored to their pre-accident condition.

Enhanced Safety Features Accelerate Repair Process

Advanced technology has significantly transformed the landscape of storm damage collision repair, introducing enhanced safety features that accelerate the process. Modern car repair shops now employ state-of-the-art equipment and software designed to streamline operations and ensure faster turnarounds. For instance, 3D mapping and laser scanning technologies enable precise measurements and accurate repairs, minimizing human error and the need for costly rework.

These innovations also extend to safety features like automated collision detection systems and advanced driver-assistance systems (ADAS). By quickly identifying damage, from cracked auto glass replacement to intricate car dent repair, these systems help technicians prioritize tasks efficiently. Moreover, ADAS components such as sensors and cameras can be recalibrated or replaced with greater speed and accuracy, ensuring the safety of drivers post-repair and reducing downtime for storm-damaged vehicles.

Advanced technology is transforming storm damage collision repair, making it faster, safer, and more efficient. Digital tools streamline assessment, 3D printing revolutionizes parts replacement, and enhanced safety features accelerate the entire process. These innovations not only improve the customer experience but also contribute to a more resilient and sustainable automotive industry in the face of increasing severe weather events.